Our final presentation can be found at the following link:

https://docs.google.com/presentation/d/1JwBJzWr3IdKkXzVigo3zbbM_hvbLNba4uZnZEZjmMrs/edit?usp=sharing

Please note that this is the final upload version, which means that we've retracted all confidential information and it is not the same version we showed in class. Ultimately, most of the material is still the same.

On behalf of the Full Scale (now Supports and Railing) team, we are excited to be done and to showcase our project at Maker Faire this weekend. It was a great experience and we are proud of our work for this semester. I hope that future teams can also implement our work to the actual full scale model at some point in the future. We're grateful to Dr. Furman, Ron, and Eric for letting us work on this project and for giving us such positive feedback over the entire year. We look forward to graduation!

Full Scale Test Track

Wednesday, May 17, 2017

Wednesday, May 10, 2017

Week 27 Progress (2017-5-10)

Vander-Bend has still not gotten back to us. At this point, we don't think the stub column will be fabricated. We still have the model that Andries gave to us, though, so we will bring that to Maker Faire to demonstrate the column's geometry.

Claude has been diligently working on piecing together all of the acrylic parts. The columns and guideway sections are now completely together and the footings are attached. Everything is ready to assemble and go to Maker Faire.

As for the PVC and wooden models, those have been completed for a couple weeks now. In class on Wednesday, 5/10, we will be attaching the PVC flanges and wooden platforms to the base as footings. Then they will be 100% complete. Now, we will work on our final presentation, which we present on Friday, 5/12, to the department.

Claude has been diligently working on piecing together all of the acrylic parts. The columns and guideway sections are now completely together and the footings are attached. Everything is ready to assemble and go to Maker Faire.

As for the PVC and wooden models, those have been completed for a couple weeks now. In class on Wednesday, 5/10, we will be attaching the PVC flanges and wooden platforms to the base as footings. Then they will be 100% complete. Now, we will work on our final presentation, which we present on Friday, 5/12, to the department.

Tuesday, May 2, 2017

Week 26 Progress (2017-5-3)

Vander-Bend has not emailed us since April 21, though Kathlyn has sent follow-up emails. At this point, if they still take 3 weeks to fabricate, we will not be able to manufacture the column stub in time for Maker Faire.

Claude has made much more progress on his model, since he was finally able to laser cut his parts. He spent a lot of time redesigning the parts for the laser cutter due to minimum spacing requirements, configuration adjustments, and adding a new part. He also made a newer version of the SOLIDWORKS model the whole assembly (minus the footings). More images related to this can be found on his blog in the post titled "Back on Track" and "Approaching Completion" at http://claudemichel-spartansuperwayblog.blogspot.com/

Claude has made much more progress on his model, since he was finally able to laser cut his parts. He spent a lot of time redesigning the parts for the laser cutter due to minimum spacing requirements, configuration adjustments, and adding a new part. He also made a newer version of the SOLIDWORKS model the whole assembly (minus the footings). More images related to this can be found on his blog in the post titled "Back on Track" and "Approaching Completion" at http://claudemichel-spartansuperwayblog.blogspot.com/

Kathlyn has been looking for PVC flanges online while Claude has gone in person to a few hardware stores. These flanges will serve as our footings for our entire architectural model. For Claude and Kathlyn's models, which use PVC as the column outside, the base diameter needs to be 1". For Winter's, which uses a slightly larger size of square-based wood, the base diameter needs to be 1 1/4". The flange would then be attached to some stock wood found in the Superway Shop.

Wednesday, April 26, 2017

Week 25 Progress (2017-4-26)

We are now waiting on Vander-Bend to look over our interlocking column blueprints so that they can be manufactured. They've given us an estimate of $115 for the sheet metal, for 0.119 inch thickness. Assuming fabrication time will still be three weeks, we might not have it ready for the Senior Project Presentations, but it should be ready for Maker Faire.

We have all made a bit more progress on the architectural models.

Claude has been working on his Palm Tree design, though he's run into complications due to the laser cutter for his acrylic. His original pattern was designed with the laser cutter in the mechatronics lab in mind, but it still isn't working. When he showed it to Kyle Meininger, he pointed out that it would not work with the laser cutter in the advanced engineering lab as the shared laser cutter line would drop the parts before they would be properly finished. As such he is currently remaking the pattern to be on two sheets so that the necessary spacing on the parts can be possible. On a more positive note, He has confirmed that the last batch of parts from Dr. Youssefi had the desired dimensions, and the last set of 3D printed parts are in production (three pairs of the small clamps and one cap) and will just need some blue tape to ensure a snug fit with the PVC pipe exterior.

Kathlyn has obtained foam pipe and attached it to her Cat's Eye design to make it more visually-appealing.

We have all made a bit more progress on the architectural models.

Claude has been working on his Palm Tree design, though he's run into complications due to the laser cutter for his acrylic. His original pattern was designed with the laser cutter in the mechatronics lab in mind, but it still isn't working. When he showed it to Kyle Meininger, he pointed out that it would not work with the laser cutter in the advanced engineering lab as the shared laser cutter line would drop the parts before they would be properly finished. As such he is currently remaking the pattern to be on two sheets so that the necessary spacing on the parts can be possible. On a more positive note, He has confirmed that the last batch of parts from Dr. Youssefi had the desired dimensions, and the last set of 3D printed parts are in production (three pairs of the small clamps and one cap) and will just need some blue tape to ensure a snug fit with the PVC pipe exterior.

Kathlyn has obtained foam pipe and attached it to her Cat's Eye design to make it more visually-appealing.

Winter took the wooden Cat's Eye model home to paint it all white. She also had Professor Youssefi 3D print a few pieces to explain how the guideway railing will attach to the column structure.

Tuesday, April 18, 2017

Week 24 Progress (2017-4-19)

We've made more progress on both the architectural model and the column stub.

First for the stub, since we finally received the blueprints from our contact's team, we can have Vander-Bend manufacture our part. We signed a Non-Disclosure Agreement first with our contact, then had Vander-Bend sign the NDA. Once this was complete, we sent Vander-Bend the files. We are still awaiting confirmation of commencing construction, as well as receiving an invoice.

Claude has made more progress on his Palm Tree design. All of the clamps types have been printed and the designs effectively finalized. He is currently working on making the laser cut acrylic for the supports and guideway parts. his cutting pattern is almost done, but he ran into technical difficulties with the Mechatronic lab's printer and is contacting Dr. Barez and Dr. Obi about the Advanced

Manufacturing Lab laser cutter.

Kathlyn has been working on communicating with Vander-Bend, and has mostly finished the PVC model of the Cat's Eye. She still needs to obtain foam pipe to make it look more visually appealing.

Winter got two clamps 3D-printed by Professor Youssefi. Kevin worked on filing down the wooden model so that the clamps would fit on. The wooden Cat's Eye model is almost complete, we just need to work on footings.

First for the stub, since we finally received the blueprints from our contact's team, we can have Vander-Bend manufacture our part. We signed a Non-Disclosure Agreement first with our contact, then had Vander-Bend sign the NDA. Once this was complete, we sent Vander-Bend the files. We are still awaiting confirmation of commencing construction, as well as receiving an invoice.

Claude has made more progress on his Palm Tree design. All of the clamps types have been printed and the designs effectively finalized. He is currently working on making the laser cut acrylic for the supports and guideway parts. his cutting pattern is almost done, but he ran into technical difficulties with the Mechatronic lab's printer and is contacting Dr. Barez and Dr. Obi about the Advanced

Manufacturing Lab laser cutter.

Kathlyn has been working on communicating with Vander-Bend, and has mostly finished the PVC model of the Cat's Eye. She still needs to obtain foam pipe to make it look more visually appealing.

Wednesday, April 12, 2017

Week 23 Progress (2017-4-12)

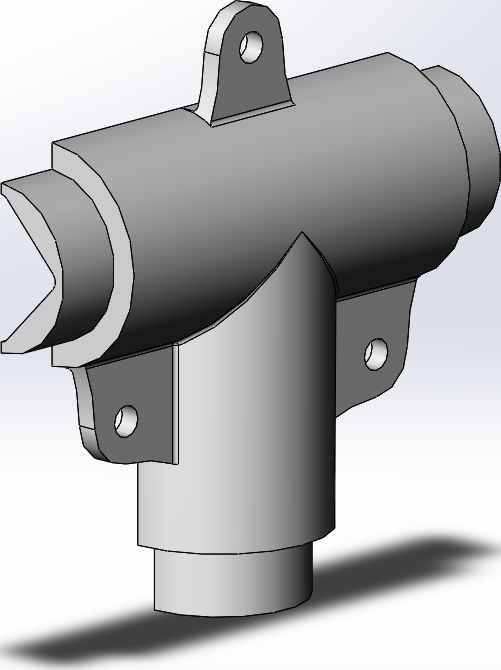

On Friday, 4/7, Winter and Kevin went to the ME computer lab to progress on the wooden model. We designed a rough model of what currently exists for the wooden parts, then designed two clamps that will be used to connect the interlocking column to the wooden structural part, because that area cannot be bolted or welded. The model is shown in the following picture:

Winter emailed the clamp files to Professor Youssefi for 3D printing, but she is still waiting on a response from him.

Next, Claude gave the completed wooden interlocking column to Winter, so it can be attached when the clamps are finished. He also completed the wooden parts for his model, and is currently trying to refine the simplified guide way for it.

Finally, we've gotten a response from Andries containing the blueprints we've been waiting three months for! After signing a Non-Disclosure Agreement (meaning there won't be specifics on this blog regarding those models in the future), we will be set to fabricate. Kathlyn has already contacted Vander-Bend and we are still looking at a fabrication time estimate of three weeks for completion.

Monday, April 3, 2017

Week 22 Progress (2017-4-5)

Over spring break, Claude and his father used the table saw to cut the interlocking columns out of 2x2 wood for everyone to use. Also, Claude finalized some of his CAD work for the "palm tree" model of our three structures for the architectural model. He recontacted Dr. Youssefi for the revised clamps, and we likely will have the new sizing prototypes on Friday. Also, He began work designing the template for the laser cut acrylic parts, which will act as the supports and guide way structures. Shown below is one of the new clamps as well as the first draft the acrylic sheet pattern.

Winter and Kevin didn't get too much progress completed on the wooden prototype, but as a reminder, it is shown below. Next steps are to design some kind of clamp to demonstrate how the connections at the top, bottom, left, and right would work. In the next few days, Claude will give Winter a piece of the interlocking column so they can design around those dimensions.

Finally, Kathlyn worked on her prototype, which is made out of PVC pipe. She heated it over the stove, then bent it to a different cat's eye shape according to rough dimensions. The models she created are shown below, though we will probably use the top design to differentiate from the wooden model above.

Finally, we worked on our Presentation 2, which will be presented on Wednesday, and therefore the link will be posted on the blog next week. We also will work on our individual writing assignments by Friday.

Subscribe to:

Posts (Atom)